Do you also recognize this problem?

Video EcoTab 2021:

EcoTab 2021 from Dicar BV on Vimeo.

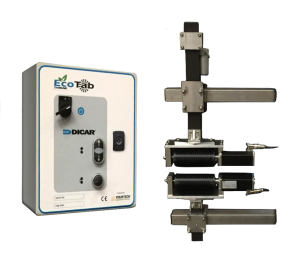

Example on an Emba

Eco Tab 427.052.002E

Eco Tab 427.052.002E

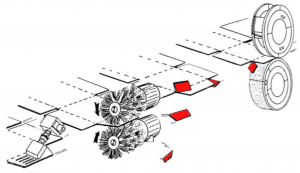

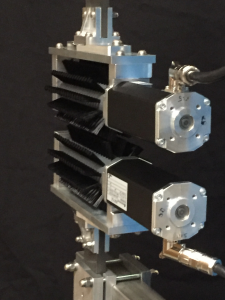

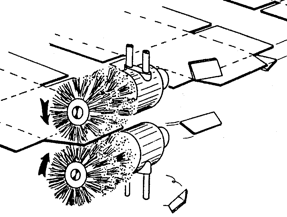

EcoTab brush system

Because the height of the brushes of the EcoTab brush system can be adjusted from the outside, it is possible to adjust the system without having to open the machine, regardless of the thickness of the cardboard to be processed. Thanks to an electric coupling of the EcoTab brush system with the feeder of your machine, the system will be activated only when boxes are actually being produced. This saves energy and prevents any unnecessary burden on the motors.

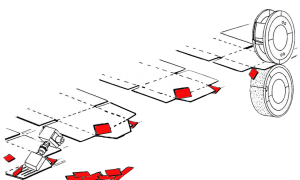

EcoTab waste removal system drawing

An investment in the EcoTab brush system earns itself very quickly. It prevents unforeseen production stops as a result of waste that interrupts the gluing process and it contributes to reducing potential return shipments by your customer because of waste left behind in the end product or poor gluing.

| EcoTab Brush system | ||

| Energie use of System | Approx.400 Watt/h | 2 Motors for driving brushes |

| 1 Motor for height adjustment | ||

ECOTAB WASTE REMOVAL SYSTEM from Dicar BV on Vimeo.

Door de site te te blijven gebruiken, gaat u akkoord met het gebruik van cookies. meer informatie

De cookie-instellingen op deze website zijn ingesteld op 'toestaan cookies "om u de beste surfervaring mogelijk. Als u doorgaat met deze website te gebruiken zonder het wijzigen van uw cookie-instellingen of u klikt op "Accepteren" hieronder dan bent u akkoord met deze instellingen.